There are many transformer core types used in the construction of transformers. A lot of cores are made from thin steel knock outs laminated together to form a solid metal core.?Laminated cores are preferred because a thin layer of oxide forms on the area of each lamination and acts as an insulator to minimize the buildup of eddy currents inside the core material. The quantity of core material required for a specific transformer is determined by the power value of the transformer. The quantity of core product needed, must be met to prevent saturation at complete load. The type and form of the core normally determines the amount of magnetic coupling in between the windings and to some extent the performance of the transformer.

?

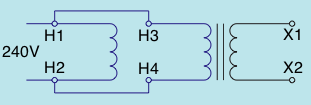

Transformer core types

The transformer illustrated above is referred to as a core-type transformer. The windings are placed around each end of the center material. As a general guideline, the low-voltage winding is placed closest to the core and the high-voltage winding is put over the low-voltage winding.

?

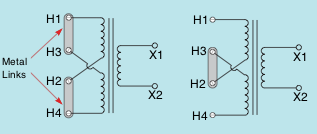

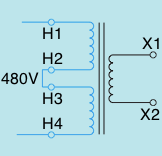

Shell-type transformer

The shell-type transformer is built in a similar manner to the core kind, except that the shell type has a metal core piece through the middle of the window (above). The primary and secondary windings are wound around the center core piece with the low-voltage winding being closest to the metal center. This plan permits the transformer to be bordered by the core and offers excellent magnetic coupling. When the transformer functions, all the magnetic flux needs to go through the center core piece. It then divides through the two external center pieces.

?

H-type Core

The H-type core received (above) is similar to the shell-type core because it has an iron core through its center around which the primary and secondary windings are wound. The H core, nonetheless, surrounds the windings on 4 sides instead of two. This extra metal helps minimize stray leakage flux and enhances the efficiency of the transformer. The H-type center is commonly discovered on high-voltage distribution transformers.

?

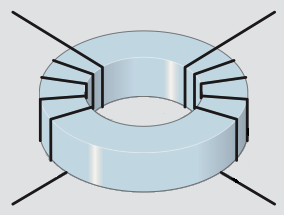

Tape-Wound Core

The tape-wound core or toroid core (above) is constructed by tightly winding one long constant silicon steel tape into a spiral. The tape might or could not be housed in a plastic container, relying on the application. This sort of center does not require steel knock outs laminated together. Because the center is one constant length of metal, flux leakage is kept to a minimum. Flux leakage is the amount of magnetic flux lines that do not follow the metal center and are lost to the bordering air. The tape-wound core is one of the most reliable core designs readily available.